Escaping the Construction Productivity Trap: A New Path for Project Success Maturity

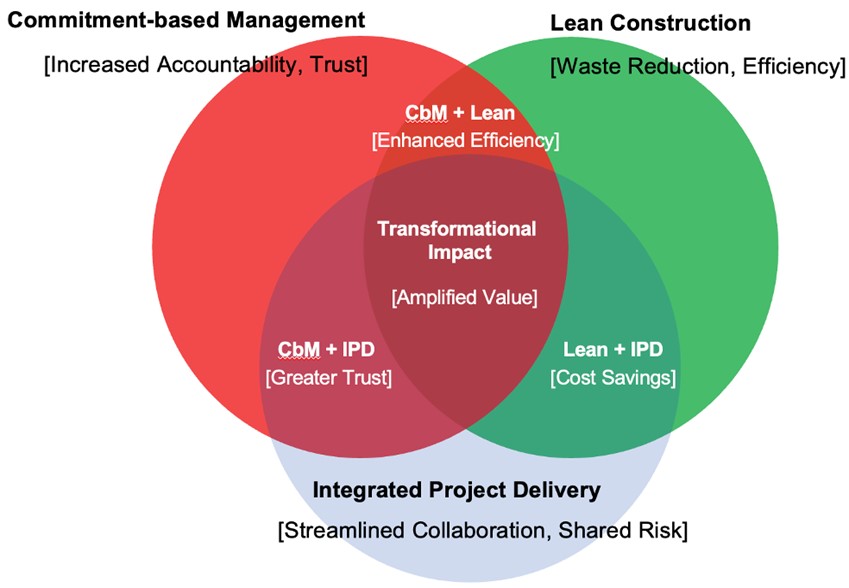

Summary: The construction industry is in a productivity crisis, with decades of decline in Canada, the UK, and the US. Efforts to address this through tighter controls and risk management have deepened inefficiencies, likened to treating diabetes with insulin while ignoring lifestyle changes. This paper advocates for a transformative shift toward adaptive, collaborative practices such as Integrated Project Delivery (IPD), Lean Construction, and Commitment-based Management™ (CbM). These methods treat construction as a Complex Adaptive System (CAS), addressing root causes by fostering trust, improving coordination, and reducing waste. Highlighting successes, including a 60% cost reduction in a Scottish Water project, the paper calls for action: begin with one project, experiment, and become part of the vanguard leading the way toward a sustainable and efficient future in construction.

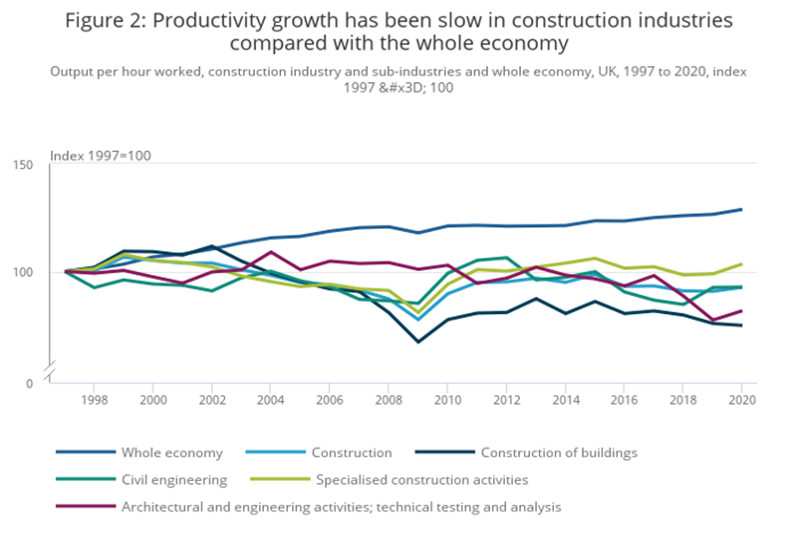

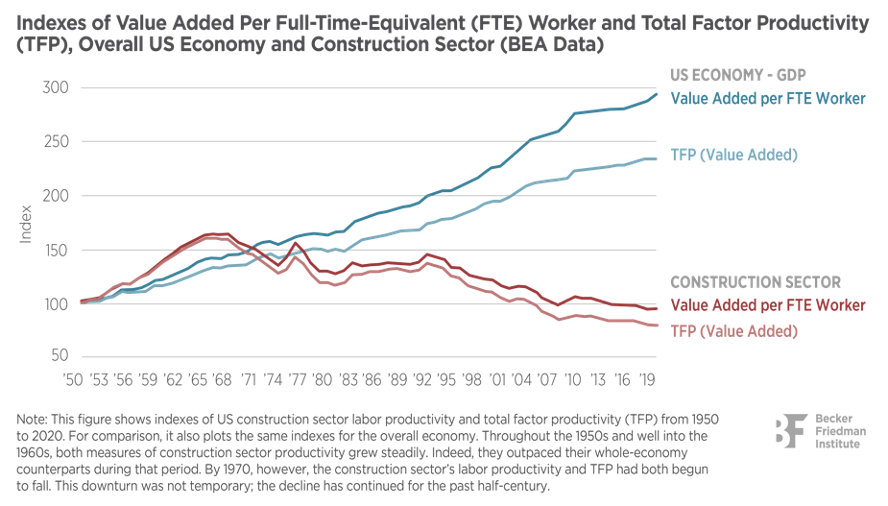

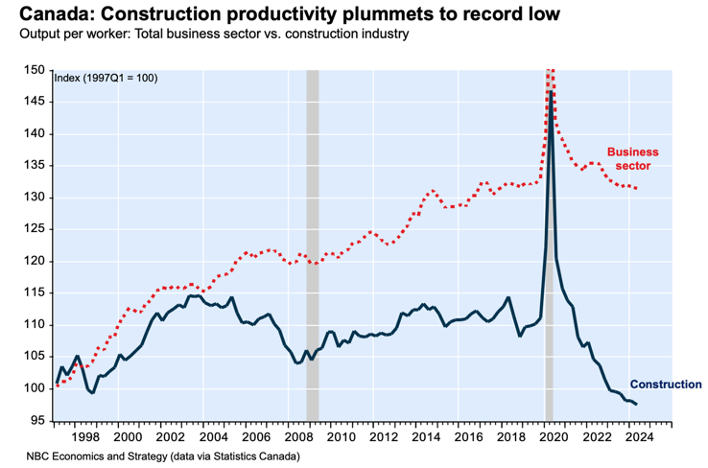

Construction productivity is at a crisis point, especially in Canada, the United Kingdom, and the United States. The data is stark: overall, in the US, construction productivity has declined by approximately 40% since 1970, even as industries like manufacturing have made great leaps forward. In the UK, construction output per hour in 2020 was 7% lower than in 1997. In Canada, September 2024 statistics also show that construction output per worker is now lower than it was in 1998, having declined for the 14th time in the most recent 16 quarters. Carolyn Rogers, Senior Deputy Governor of the Bank of Canada, likened the situation to an emergency, saying, “It’s time to break the glass.”

It might be like treating diabetes with increasing doses of insulin while ignoring the need for lifestyle changes: tighter control, stricter contracts, and risk management measures create a short-term perception of efficiency but ultimately deepen systemic issues. Instead of delivering the promised improvements, these measures may be exacerbating the problem. This narrow focus on control might stabilize the situation in the moment of contracting and pre-project planning, but leads to severe complications down the line in the form of escalating timelines, costs and disputes.

The Need for Transformational Change

The construction industry’s conventional solutions — detailed planning, strict oversight, and complex risk management — resemble a narrow medical approach that increases insulin without considering lifestyle adjustments. Like diabetes patients who need dietary and lifestyle changes, construction requires adaptive practices that go beyond conventional control measures. Conventional approaches are rooted in linear systems thinking, where projects are treated as predictable sequences of tasks. This mindset assumes that tighter control and prescriptive contracts can ensure predictable outcomes. However, construction projects today function as Complex Adaptive Systems (CAS), with many interacting parts that adapt continuously.

In a Complex Adaptive System, rigid, top-down measures miss the mark entirely. Just as managing diabetes effectively requires a holistic lifestyle change rather than simply reducing symptoms, addressing the productivity crisis in construction requires a fundamental shift in project delivery models and practices. Doubling down on methods that make sense individually but have evidently done nothing to improve the productivity situation only deepens the issues, like adding sugar to an already imbalanced system.

This might sound like a lot to take in. If you’ve been managing projects with traditional methods, the idea of a complete shift can feel daunting. But transformation doesn’t happen overnight. It starts with small, intentional steps, and you can begin today. For over 20 years, pioneers in this field have already been refining these adaptive practices, demonstrating their effectiveness in tackling the complexities of major projects in Canada, the UK and the United States. Teams and people that adopt these methods often describe a return to conventional structures as a step backward, likening it to punishment.

Rethinking Command, Contracts, and Risk Management

Projects are networks of commitments. The number of commitments increases exponentially with the size of the project. To improve performance on projects we need an operating system that increases the connectedness of people to strengthen that network of commitments.

But the industry’s instinct to tighten control and manage risk through stricter contract language is like a diabetic patient focusing only on medication while ignoring diet and exercise. It may provide short-term stability but ultimately deepens the underlying problems by ignoring the need for systemic change. Just as managing diabetes effectively requires a holistic plan of medication, diet, and exercise, addressing the productivity crisis in construction requires a fundamental shift in project delivery models and practices.

Similarly, excessive layers of risk management can give the appearance of control but often add to the complexity and rigidity of projects. In many cases, the resources spent on managing risk exceed the benefits, much like prescribing additional medication without addressing the root causes of a patient’s illness. The real solution lies in changing our approach – the lifestyle of construction contracting: building trust, improving coordination, and embracing adaptive practices, akin to helping a diabetic patient adopt sustainable, healthy habits rather than relying on temporary fixes.

The best way to proceed is to change this lifestyle one project at a time. The following practices – collaborative contracting, lean construction, and Commitment-based Management™ – are key aspects of the new lifestyle.

Breaking Free: The Case for Collaborative Contracting and IPD

Collaborative contracting strategies increase the bond on the network of commitments by aligning all the parties involved in the contract on a common goal. In traditional contracts, the incentives are aligned for one party to benefit at the expense of others. The remedy for this has been more control (insulin) to force people to behave properly. But the result has been what we call coordination waste, either in the form of waiting, excess bureaucracy, doing the wrong thing that will have to be corrected later, or doing things that do not add value to the project. Incentives – what’s in the contract – drive those behaviors. A more natural approach is to align the incentives so all parties benefit when the project benefits.

Collaborative contracting models, particularly Integrated Project Delivery (IPD), provide an alternative to the traditional reliance on risk transfer and prescriptive contracts. To sketch a case in point around the illusions of certainty and control produced by traditional contracting, a Canadian infrastructure project – a new wastewater treatment plant – was contracted on a $525M fixed price, fixed schedule basis in 2017. Between 2018 and 2021, change orders took the “fixed price” first to $621M, and finally to $1B in 2021, when the contract fell apart. The parties are suing each other for $400M and $250M, which will cost the construction company and taxpayers millions in legal fees. But the shocking element came in 2023/24, when a new round of estimates, cost-plus design and remediation work indicated that the final cost would be $3.84B. Were project designers constrained by culture and corporate conventions to prescribing more insulin, rather than tackling the disease holistically?

In contrast, IPD aligns participants around shared goals, encouraging collaboration similar to a comprehensive diabetes treatment plan that integrates lifestyle changes, diet, monitoring, and patient education for long-term success. However, implementing IPD without actively developing and fostering a culture of adaptability and mutual accountability is like increasing a diabetic patient’s medication without addressing their diet and exercise habits. The true power of IPD lies in its ability to offer a structure that provides a supportive environment to foster new behaviors that address systemic issues of inefficiency and relationships by making it easier to build a culture of trust, mutual accountability, and shared success, akin to helping a diabetic patient adopt sustainable, healthy habits rather than relying on temporary fixes.

Lean Construction: Increasing Efficiency in Delivery

Lean Construction principles are crucial in tackling inefficiencies that tighter control measures fail to resolve. Studies show that up to 85% of work time in construction is wasted on non-value-adding activities, such as waiting – for materials, inspections, approvals, etc. – or dealing with excessive bureaucracy. Lean techniques like the Last Planner System® transition from rigid, top-down scheduling to a flexible ‘pull’ model that adapts to actual project conditions, reducing waste and improving efficiency by responding to real-time needs.

Lean Construction approaches reinforce the notion of conducting projects as dynamic networks of commitments. Rather than treating tasks as isolated actions to be performed by someone as if they are a cog in a machine, Lean emphasizes the interconnected nature of promises made between team members, where each commitment serves as a link in a chain of project delivery. This perspective aligns with phase pull planning, where the process begins by collaboratively defining the conditions of satisfaction for each phase. Here, performers adopt a customer mindset, treating the subsequent task or trade as their customer and negotiating the specific outcomes required. This negotiation is not a one-time event, but an evolving practice, where promises are continuously managed and adapted in response to the project’s real-time needs. By focusing on explicit commitments and reliable delivery, Lean Construction shifts away from rigid control and embraces a more fluid, adaptive approach that is essential for handling the complexities of modern projects.

Moreover, implementing the Last Planner System exemplifies how Lean Construction manages these commitments through structured practices like end-of-shift stand-up meetings, where trade partners can update their promises and report completions. This approach not only enhances transparency but also strengthens the network of commitments by enabling rapid adjustments and mitigating delays before they escalate. In this way, Lean Construction integrates the principles of Commitment-based Management (CbM), prioritizing reliable promises over strict adherence to static schedules. It creates a collaborative environment where project performers are empowered to renegotiate commitments when unforeseen challenges arise, ensuring that the network remains resilient and responsive. This adaptability is crucial, as it allows the project team to address emergent conditions effectively and maintain momentum toward successful delivery.

Rather than adding more layers of control — the construction equivalent of prescribing more medication — Lean Construction emphasizes seeing the project as a network of commitments, becoming rigorous and effective in managing promises, eliminating waste and simplifying processes. It’s about treating the root causes of inefficiency, just as effective diabetes management focuses on dietary and lifestyle adjustments rather than merely addressing symptoms with medication.

CbM: Improving Relationships and Driving Action

At the heart of Lean Construction is Commitment-based Management (CbM), which builds trust through explicit promises and reliable commitments, rather than enforcing compliance through rigid oversight. CbM focuses on building a culture of trust through reliable promises and shared goals, similar to how diabetes management requires consistent habits and self-monitoring for long-term health, rather than asking people to act as cogs in a project management software machine that “tasks” them as though they are robots. It shifts the focus from what people are required to do to what they promise to deliver, enhancing accountability and fostering a culture of trust.

While this may seem obvious, it is in reality and practice not obvious at all. Apart from moral slogans (“keep your promises”), there is a general underdevelopment of skill in intentionally managing promises and coordinating action that shows up as distrust and project schedules that anticipate and cost for delays.

Creating a culture that supports Lean Construction and Integrated Project Delivery (IPD) requires more than just process changes; it demands a fundamental shift in how people communicate, collaborate, and make commitments. This shift begins by introducing the project team to essential language distinctions that drive action, such as offers, requests, promises, assessments, assertions, and declarations. In practical terms, these distinctions help team members to clearly articulate what they are committing to, negotiate realistic expectations, and understand the conditions of satisfaction (COS) that define successful delivery. Initial workshops provide a structured environment where teams learn and practice using this new language, reframing interactions through a customer-performer lens, where trust is built through consistent delivery on well-defined promises.

The transformation doesn’t end with workshops, however. To truly embed these practices, experienced coaches work alongside the project team, offering in-the-moment nudges and feedback that help reinforce the use of these distinctions in daily conversations. Regular learning team sessions create a space for reflection, allowing the team to collectively examine how their commitments, offers, and requests played out in recent work, identifying both successes and areas for improvement. This iterative, reflective practice anchors learning in the real-world context of the project, making it pragmatic and immediately applicable. Over time, what begins as classroom knowledge evolves into embodied ways of being—automatic, intuitive behaviors that form the foundation of a new project delivery lifestyle. This continuous learning practice is key to sustaining a high-functioning network of commitments, where trust and reliable promises are the norm rather than the exception.

In a project with Scottish Water, Lean and CbM principles reduced time to site by 50% and cut costs by up to 60%, demonstrating the impact of integrating cultural change alongside process improvement and contract shifts (the work occurred under a collaborative Alliance Framework), much like a holistic diabetes management plan.

Why This Matters Now

The stakes are high. Public sector organizations managing megaprojects face a choice: continue with the status quo, relying on tighter control, stricter contracts, and more risk management, or embrace a different approach that addresses the root causes of inefficiency. Persisting with current methods is like continuing to treat diabetes with medication alone while neglecting necessary lifestyle changes. The escalating costs and stagnant productivity metrics tell the story—one where the status quo presents greater risks than trying something new, particularly for professionals looking to enhance their contributions to project success.

In the case of the Canadian project referenced above, inflation of about 65% in materials and labour between 2017 and 2024 might explain a rise from $525 million to $866 million. But the leap to $3.84 billion reflects something else: systemic waste — the outcome of an industry that has doubled down on methods that – without lifestyle changes, or changes in the way work is procured, managed, and delivered — exacerbate rather than alleviate the problem.

The Path Forward

- Start with one Project: Assemble a team willing to learn to do things in a new way.

- Invest in Collaborative Contracting Models: Adopt IPD to align stakeholders, reduce adversarial relationships, and foster shared success.

- Move Beyond Command and Control: Shift from rigid oversight to adaptive decision-making that can respond to dynamic project conditions.

- Embed Lean Principles Across Projects: Use Lean techniques to streamline processes, cut waste, and empower frontline decision-makers.

- Build a Culture of Trust and Commitment: Embrace a behavioral approach that builds trust and fosters reliable promises, moving away from distanced tasking.

- Seek Expert Guidance: Partner with leaders who understand the need for transformational change and can guide the implementation of new practices.

The Opportunity Ahead

The construction industry’s productivity challenges are not new, but persisting with the same conventional strategies seems to be having the cumulative effect of treating diabetes with something that amounts to… more sugar. It’s time to break this cycle and embrace a holistic, adaptive approach — one that values collaboration, flexibility, and trust over rigid control. By integrating collaborative contracting, Lean Construction, and Commitment-based Management, we can escape the productivity trap, deliver projects more efficiently, and build a more rewarding work environment for everyone involved.

Public sector entities are in a unique position and have an opportunity to lead by setting a new standard for critical infrastructure delivery and project affordability. Let’s stop treating the symptoms, and start addressing the root causes — the future of construction depends on it. As Carolyn Rogers says, “It’s time to break the glass.”

This is also an opportunity for individuals to build their capacity to lead and contribute to these transformative changes. By learning and practicing the skills that establish and sustain collaborative contracting, you position yourself as a valuable player in the future of infrastructure delivery.

Start by choosing one important project to experiment with these new practices. Reflect on the outcomes and build on the wins. With each step, you’ll begin to see the power of this approach. This isn’t about perfection; it’s about learning, progress and starting a journey toward a more effective way of delivering projects.

To learn more, reach out to VISION Consulting www.vision.com or our construction partner Relevate www.relevatewith.us

Further Reading and Resources

These resources are more than academic—they’re starting points for practical action. Use them to spark conversations within your teams about how upcoming projects could serve as testbeds for these innovative practices.

- Donald Sull, Charles Spinosa, “Promise-Based Management: The Essence of Execution,” Harvard Business Review

- James Pease, Renee Cheng, Markku Allison, Howard Ashcraft, “Integrated Project Delivery: An Action Guide for Leaders”

- Hal Macomber and Connor Butler, “Revisiting the 5 Big Ideas about Lean Construction: Projects as a Network of Commitments,”

- Peter Luff, “Reliable Promises 101,” Lean Construction Blog

Source: National Bank Financial Economics and Strategy, September 2024